- Shopping, made easy.

- /

- Get the app!

Cloisonne, known as "copper tire wire enamel", is a famous traditional handicraft in Beijing, China. It is made of thin flat copper wire, combines the delicate shapes produced by the filigree technique with the splendid color decorations of enamel to create handicrafts that are exquisitely shaped, brightly colored, and highly ornamental and artistic in value. It originated in the Ming Dynasty of China and has a history of more than 600 years. The production technique is relatively mature, which has been recognized by many scholars. A beautiful Cloisonne ware, first of all, has a good shape, which depends on the tire; Also has a beautiful decorative pattern, which is determined by the wire; Gorgeous color depends on the preparation of blue material; The brilliant luster is finished with polishing and gilding. Therefore, it is a collection of art, craft, engraving, Mosaic, glass melting, metallurgy, and other professional technologies as a whole, with a distinct national style and profound cultural connotation, is one of the most Beijing characteristics of the traditional handicrafts. Because of its historical significance and craftsmanship, Cloisonne was listed as the first batch of intangible cultural heritage by the state in 2006, and Cloisonne is the best art treasure worth appreciating, collecting, and giving gifts. The main steps for making cloisonne paintings are as follows: 1. Designing the Sketch - Initially, ascertain the theme of the painting, encompassing but not limited to landscapes, figures, and floral or avian motifs. - Draft a preliminary sketch on paper by the chosen theme. Carefully plan the composition, ensuring each element's position and proportional relationship are accurately determined. Preparing Materials - Baseboard: Materials such as wooden boards or composite panels are typically utilized. The surface must be perfectly flat and smooth before being cut into appropriate dimensions. - Glaze: Prepare an array of cloisonné glazes in various colors. It is essential that these glazes possess pure hues and finely ground particles. - Metal Wire: Primarily, soft yet resilient flat copper wire is used, facilitating ease in bending and shaping. - Miscellaneous Tools: Equip oneself with necessary tools including tweezers, spatulas, and adhesive. 2. Wire-bending - Employ tweezers to meticulously bend and shape the metal wire following the contours of the sketched pattern, ensuring it adheres closely to the design lines. - Securely affix the shaped wire onto the baseboard using adhesive. During this process, ensure precise positioning and firm adhesion of the wire. 3. Applying Glaze - Utilize tools such as spatulas to fill the areas delineated by the metal wire with glaze. - Ensure even application of the glaze, paying close attention to the seamless transition between different colored glazes. Mixing colors as required is permissible. 4. Drying - After applying the glaze, place the artwork in a well-ventilated area to dry naturally, allowing the moisture within the glaze to evaporate. - Throughout the drying phase, take precautions to prevent dust or other contaminants from settling on the artwork. 5. Application of Sealant Ensure that sealant is applied after the glaze has completely dried. This will facilitate the cohesion of the colored glaze, preventing loosening, and create a waterproof barrier to enhance the durability of the work. The drying process typically requires approximately 12 hours to achieve full curing. 6. Framing - Pair the finished piece with an appropriate frame to enhance both its aesthetic appeal and protection.

-7%

Candle Warmer Lamp, Dimmable Electric Candle Lamp Warmer with 2 Bulbs, Glass Candle Warmer Lantern Fragrance Wax Melt Warmer for House Decoration, Amber

KWD 7

-7%

Candle Warmer Lamp, Dimmable Electric Candle Lamp Warmer with 2 Bulbs, Glass Candle Warmer Lantern Fragrance Wax Melt Warmer for House Decoration, Amber

KWD 7

-10%

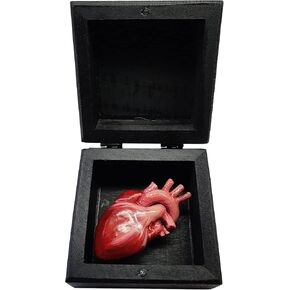

3D My Heart in A Box Handmade Carved Heart Shape Gifts Wooden for Her or Him - Christmas, Valentine's Day, Mother's Day, Father's Day, Birthday(Black Box)

KWD 4.500

-10%

3D My Heart in A Box Handmade Carved Heart Shape Gifts Wooden for Her or Him - Christmas, Valentine's Day, Mother's Day, Father's Day, Birthday(Black Box)

KWD 4.500

Horror Movie, Popular Rug, Themed Rug, Cool Rug, Area Rug, MR60 (23"x31")=60x80cm

KWD 20

Horror Movie, Popular Rug, Themed Rug, Cool Rug, Area Rug, MR60 (23"x31")=60x80cm

KWD 20

B H Handicrafts Handmade Votive Gold Tealight Candle Holders Stand Decorative Tabletop Pillar Candlestick for Wedding Decoration Vintage Style Perfect for Centerpieces Home Decor Gifts (Pack of 1)

KWD 3.500

B H Handicrafts Handmade Votive Gold Tealight Candle Holders Stand Decorative Tabletop Pillar Candlestick for Wedding Decoration Vintage Style Perfect for Centerpieces Home Decor Gifts (Pack of 1)

KWD 3.500